SEARCH

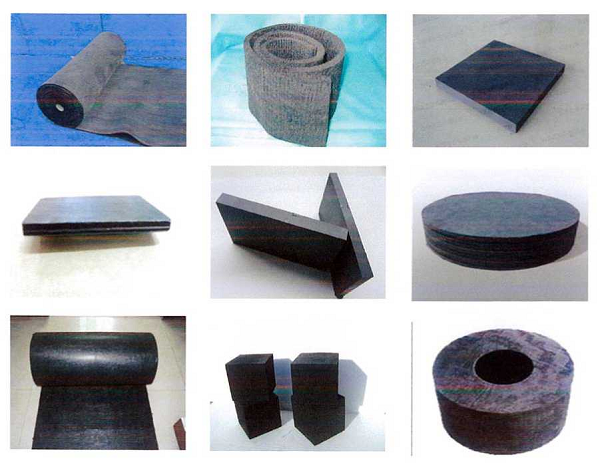

Product name:Uetersen carbon fiber composites

Category:Install service

Add time:2022-08-09

Desc:Carbon fiber composite materials are made of man-made chemical fibers with high carbon content that do not melt during heat treatment, compounded with organic fiber resins, metals, ceramics and other substrates, and are made by thermally stable oxidation ...

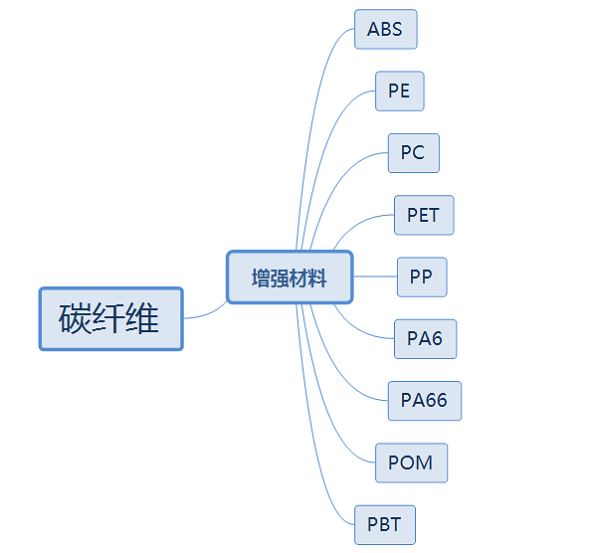

Carbon fiber composite materials are made of man-made chemical fibers with high carbon content that do not melt during heat treatment, compounded with organic fiber resins, metals, ceramics and other substrates, and are made by thermally stable oxidation treatment, carbonization treatment and graphitization. Inorganic fiber composite reinforcement. Low density, antistatic; excellent fatigue resistance and creep resistance; good wear resistance, self-lubrication and friction, high thermal and chemical stability, excellent mechanical properties, close to metal materials, is an alternative Ideal material for metals such as copper, cast zinc, aluminum, etc.

Carbon fiber composite materials for motor vehicles (sound-absorbing and cold-proof cotton)

The carbon fiber sound-absorbing and cold-proof cotton of Uetersen Company is made of 1.5D polyacrylonitrile fiber. The organic and harmful substances in the fiber are burned in a 350-degree furnace, and the organic fiber is converted into an inorganic fiber, which contains oxygen. With an index of about 50, it is incombustible and insoluble in an open flame, and no smoke and toxic gases are produced.

Carbon fiber sound-absorbing and cold-proof cotton, produced by non-woven method, has low thermal conductivity, excellent thermal insulation, sound insulation and sound absorption performance, no fire reaction, no dripping, no smoke and poisonous gas. The combustion level is DIN5510-2-2009, S-4, the smoke level is SR-2, the dripping level is ST-2, and the smoke toxicity reaches DIN5510-2-2009 Railway Vehicle Fire Protection Part II: Combustion Requirements for Materials and Components As well as the test requirements described in the test method, it can also meet the test requirements of BS6853-1999.

Carbon fiber sound-absorbing insulation material for air duct

The special carbon fiber sound-absorbing and thermal insulation cotton for air duct developed by Uetersen New Materials Group Co., Ltd. is made of carbon fiber, polyester fiber and environmentally friendly binder through a special process. According to the needs of the current rail transit weight reduction design, According to different requirements, it can be made into sound-absorbing cotton insulation sheets with different thickness and different bulk density (density), and the minimum bulk density can be 8-11kg/m3.

Uetersen New Materials Group Co., Ltd. can also provide various veneer materials (high-strength fireproof and moisture-proof aluminum foil veneer, glass fiber cloth veneer (and black), aluminum foil glass fiber cloth veneer, carbon fiber veneer, etc.), and in On the ex-factory composite carbon fiber sound-absorbing insulation cotton, there are different models and items to choose from. The adhesive selected for carbon fiber cotton and veneer is a flame-retardant, moisture-proof and environmentally friendly adhesive, which is specially used for clothing and other adhesives that come into contact with the human body. It can meet the hazard level requirements of EN45545-2R1HL3.

Carbon fiber composite materials not only have excellent thermal insulation, sound insulation and sound absorption performance, but also have the advantages of high temperature resistance, friction resistance, electrical conductivity, thermal conductivity and corrosion resistance. Electromechanical equipment and other modern industrial and high-tech fields.

1. Aerospace applications: The application of carbon fiber composite materials in key parts of modern aerospace is recognized, including primary and secondary components on Boeing aircraft and Airbus commercial aircraft, in the International Space Station, satellites, rocket engine casings and consumption launch vehicles In addition, carbon fiber composite materials are also widely used.

2. Industrial application: New-purpose carbon fiber composite materials are developing rapidly. From taking the load off firefighters to making lighter fuel tanks that carry more fuel in cars, fiber composites are replacing traditional heavy metal pressure vessels. Improve x-ray equipment, energy storage batteries, ground antennas, wind turbine blades and rollers on industrially processed paper, but only a few applications of carbon fiber composites can change our lives.

3. Recreational applications: Typical products include golf club shafts, commercial and game fishing rods, wind surfing equipment, bicycle parts, ski equipment and tennis rackets, America's Cup sailboats and other high-performance boats, etc.

4. Carbon fiber composite materials also have transient temperature measurement devices on the surface of high-speed aircraft fairings, violin soundboards, oil-free bearings, anti-collision bumpers for motor vehicles, ships, submarine propellers, air compressor materials, high strength, high Flexible new sports springboards, flying equipment and other applications.

Carbon Fiber Reinforced Thermoset Composites

Because of its high strength, its tensile strength is 8-10 times that of ordinary steel, its strength modulus is better than that of steel, it has excellent creep resistance, corrosion resistance and fatigue resistance, its thermal expansion coefficient is small, and its weight is light. It is only 1/5 of steel, and has the characteristics of easy X-ray penetration and absorption rate. Widely used in aerospace, military industry, sporting goods, machinery and equipment, shipbuilding industry, automobile industry, building reinforcement, medical equipment, rail transit and other fields.

Carbon fiber felt, carbon fiber graphite felt

It is made of PAN-based and viscose-based carbon felt as the base material, which is compounded and carbonized by special adhesives and stone-ground. It has certain rigidity, self-support, small specific gravity, no short fiber falling off, low thermal conductivity, and the operating temperature can reach 3000°C. It is suitable for various furnace types such as high pressure gas quenching furnace, pressure sintering furnace, silicon carbide recrystallization furnace, single crystal silicon furnace, polycrystalline silicon furnace and so on.

This material is an ideal thermal insulation material for vacuum furnace industry, monocrystalline silicon and polycrystalline silicon industry in my country. In order to prevent fluff, the surface of this product can be treated with special coating, such as: pasting graphite paper, graphite cloth, graphite flakes, etc.